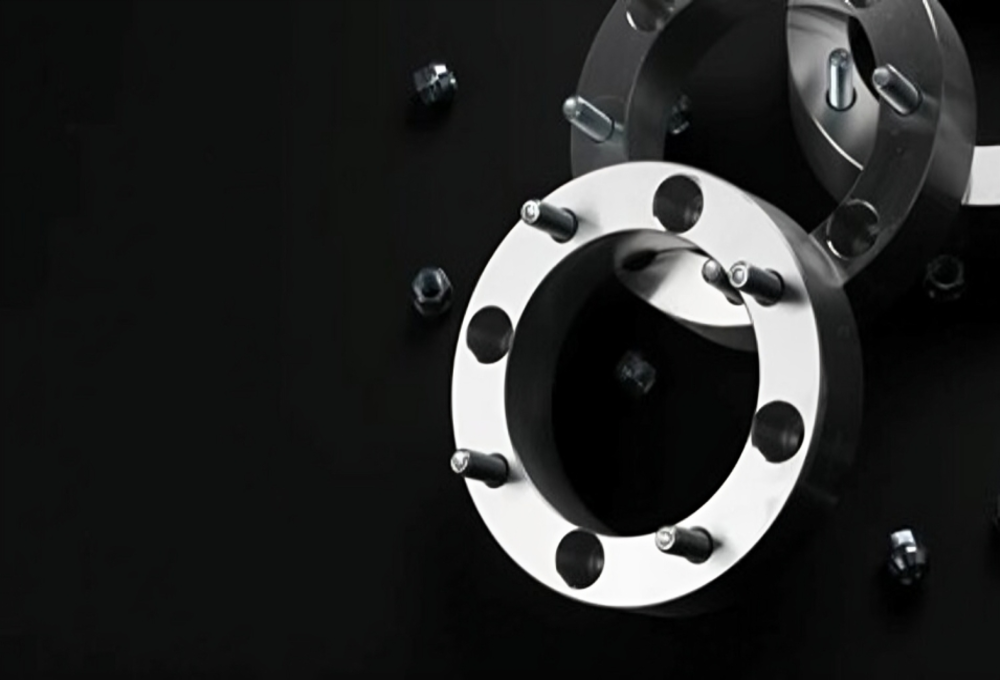

A hub centric wheel spacer is a precision-engineered component that mounts between your wheel and hub, maintaining perfect wheel alignment through a hub-centered design rather than relying solely on lug nuts for centering. Unlike universal spacers, these components are vehicle-specific and require exact measurements for safe installation.

How to Choose the Right Hub Centric Wheel Spacers

Selecting the right hub centric wheel spacer begins with understanding the central principle of wheel mounting. Your wheel's connection to the vehicle needs strong bolts, but more importantly it needs a perfectly centered, stable platform that can handle thousands of pounds of force in multiple directions.

This is where hub bore diameter becomes critical. The center hole of your wheel spacer must match your vehicle's hub diameter with sub-millimeter precision. When these diameters align perfectly, the spacer creates a solid mechanical connection that centers your wheel before the lug nuts even touch it. This mechanical centering is what prevents the microscopic movements that lead to premature wear.

But the precision requirements go deeper than just matching numbers. The hub bore's tolerance affects how forces transfer through your entire wheel assembly.

During acceleration, your wheels experience forward thrust. During braking, they face opposite forces. In corners, lateral forces try to push your wheels sideways. A proper hub centric spacer maintains perfect alignment through all these forces by creating what engineers call a "friction coupling" between surfaces.

How To Precisely Install Hub Centric Wheel Spacers

The mounting surfaces between your hub, spacer, and wheel form what engineers call "friction interfaces." These surfaces need to be more than just clean - they need to be free of microscopic imperfections that could prevent full surface contact.

This is where torque specifications become crucial. When you tighten a lug nut to the specified torque value, you're actually creating a precise amount of clamping force.

This force needs to be distributed evenly across the entire mounting surface. Too much force in one area and too little in another creates uneven stress that can lead to warping or bolt failure.

The sequence of tightening matters because it determines how this clamping force develops. Each bolt affects the tension of its neighbors.

When you follow the correct cross-pattern sequence, you're gradually building up even pressure across the entire assembly. Skip this pattern, and you create stress points that can lead to premature wear or failure.

What You'll Need for Installation

-

Torque wrench capable of reaching vehicle specifications (typically 80-100 ft-lbs)

-

Socket set matching your lug nut size

-

Wire brush or surface preparation tools

-

Degreaser or brake cleaner

-

Safety equipment (gloves, eye protection)

-

Vehicle jack and jack stands

-

Wheel chocks

-

Factory service manual or torque specifications

Surface Preparation Steps

-

Clean hub surface thoroughly with degreaser

-

Remove any rust or corrosion with wire brush

-

Clean spacer mating surfaces

-

Verify no debris remains on any contact surface

Torque Specifications and Sequence

Follow this precise sequence for optimal clamping force:

-

Hand-tighten all lug nuts

-

Initial torque to 30% of specification in star pattern

-

Secondary torque to 60% in same pattern

-

Final torque to 100% specification (typically 85-95 ft-lbs)

-

Recheck all nuts in sequence

Hub Centric vs Lug Centric Wheel Spacers (Force Distribution)

Every time your wheel turns, it generates forces in multiple directions. The hub centric spacer becomes part of your wheel's rotating assembly, which means it needs to maintain perfect balance. Any imperfection in the spacer's mounting creates a point where these forces can concentrate, potentially leading to vibration or accelerated wear.

This is where proper installation and prevention intersect. When your spacer is correctly mounted, it becomes an integral part of your wheel assembly. The clamping force created by properly torqued lug nuts maintains this integration even under extreme forces. But this clamping force can only do its job if every component in the assembly is properly prepared and positioned.

Comparison: Hub Centric vs Lug Centric Spacers

|

Feature |

Hub Centric Spacers |

Lug Centric Spacers |

|

Centering Method |

Hub bore |

Lug nuts only |

|

Load Distribution |

Even across hub |

Concentrated on lugs |

|

Installation Precision |

Critical |

Less critical |

|

Cost |

Higher |

Lower |

|

Vibration Risk |

Minimal |

Higher |

If you want to learn about this, we also have a blog addressing the difference between hub centric wheel spacers and lug centric wheel spacers.

Frequently Asked Questions

How do I know if my wheel spacers are hub centric?

Hub centric spacers have a precisely machined center bore that matches your vehicle's hub diameter. They'll include this measurement in their specifications and will fit snugly over your vehicle's hub without play.

What's the maximum safe thickness for hub centric spacers?

Generally, 25mm is considered the maximum safe thickness for most vehicles. However, this depends on your vehicle's specific suspension geometry and intended use. Performance vehicles often should stay under 20mm.

How often should I check spacer torque?

Check torque after the first 50 miles of installation, then at every tire rotation or 5,000 miles, whichever comes first. Any unusual vibration should prompt immediate inspection.

When it comes to premium hub centric wheel spacers, Orion Motor Tech delivers exceptional quality through precision engineering.

OMT’s wheel spacers are CNC-machined from T6 aircraft-grade aluminum, featuring heat-treated anodizing for maximum durability and corrosion resistance. The precision hub bore design and high-strength zinc-coated bolts ensure perfect fitment and secure installation.

With a comprehensive warranty backing their products, OMT wheel spacers offer the ideal combination of safety, performance, and peace of mind.

Looking for the right wheel spacers for your vehicle? Visit Orion Motor Tech to explore their complete line of hub centric solutions.