DIY mechanics who like to study cars may know that the engine is based on the intake of air and oil mixture into the engine cylinder combustion and explosion to generate power, and then exhaust the burned exhaust gas. And in charge of the engine intake and exhaust components is the engine valve.

What is Engine Valve?

The valve is one of the important parts inside the engine, divided into intakevalve and exhaustvalve. its appearance is similar to the shape of a horn. The intake valve is responsible for air entering the intake manifold and fuel mixing (direct injection is in the cylinder fuel supply) to enter the control of the cylinder, while the exhaust valve is responsible for the control of the exhaust gas out of the cylinder after combustion.

The previous engine has only one intake valve and one exhaust valve per cylinder, so the design is simpler and less expensive, the vehicle's low-speed response is good, but in the high speed efficiency is poor, and then in order to improve the intake and exhaust efficiency, improve the performance of the vehicle, most of the engines today are multi-valve design, the most common is the design of four valves per cylinder, to four-cylinder engines, for example, each cylinder 4 valves four cylinders is 16 valves.

The valve action is driven by a belt or metal chain that connects the crankshaft to the camshaft, and then the protruding part of the camshaft pushes the valve down to open for intake and exhaust action, while the closing action is left to the valve spring.

What is A Valve Spring?

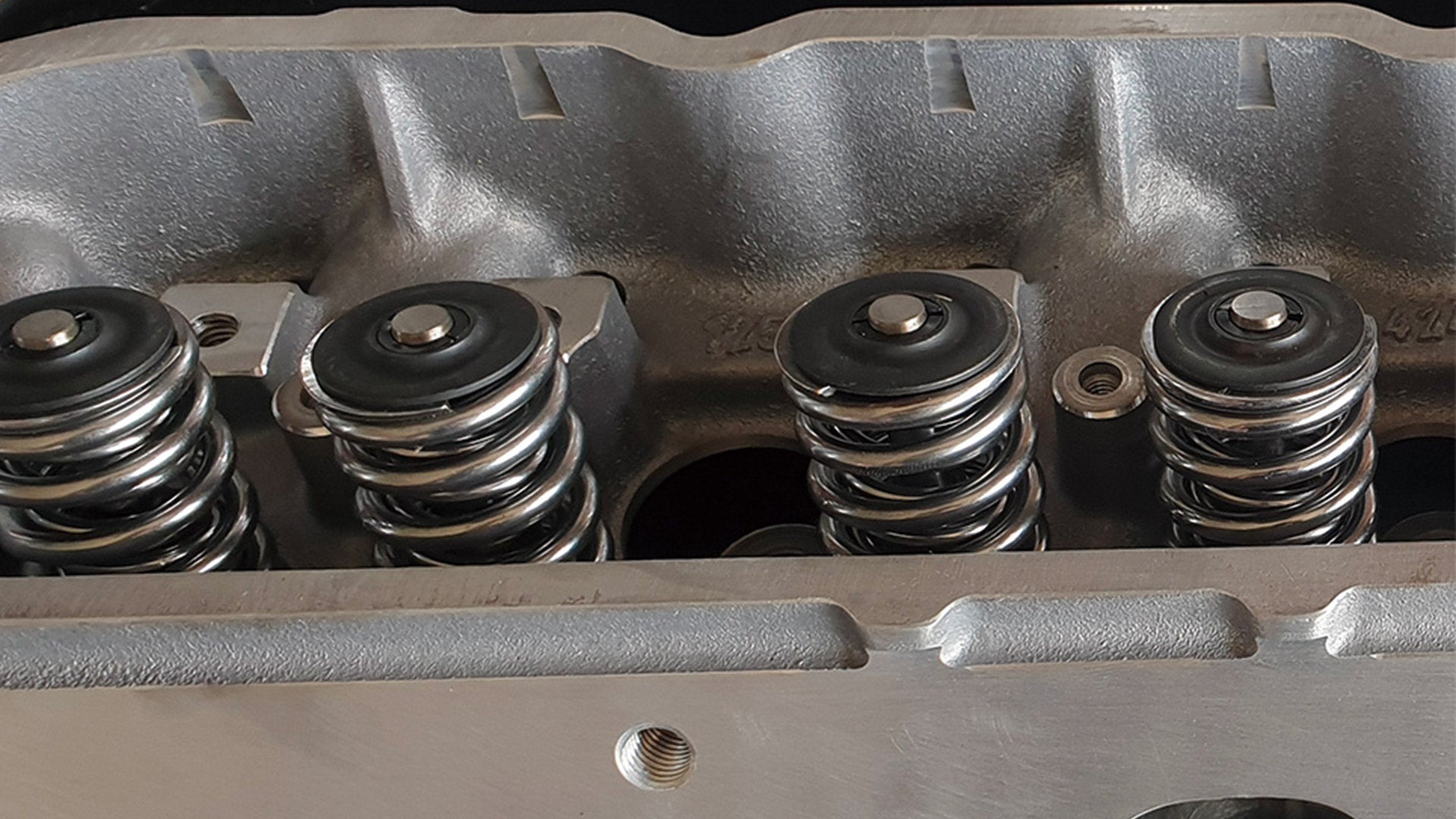

Most of the valve springs today are cylindrical spiral springs, which rely on the tension of the spring to make the open valve return to the closed position quickly. This prevents the valve from gaping during engine movement due to inertial force and ensures a tight fit when the valve is closed. It also prevents the valve from breaking the seal due to jumping during vibration.

The valve spring is located between the cylinder head and the spring seat at the end of the valve stem. The function of the valve spring is to ensure that when the valve is closed, it can closely fit with the valve seat or valve seat ring, and overcome the inertia force generated by the air distribution mechanism when the valve is opened, so that the transmission parts are always controlled by the cam and not separated from each other.

Why valve springs are important.

- The valve spring is not allowed to have any cracks, inclined surface, uneven ends or inverted use, otherwise the spring will break, and the uneven ones will increase the wear of the valve stem and the duct, causing the valve to swing closed poorly.

- Valve springs with insufficient pressure due to insufficient length make the valve close poorly or the valve close weakly, which can lead to valve working surface ablation. If the length is too long, it will produce the top surface of the cam rotation before the top spring ring has no gap, the spring will break easily, the seat ring will break easily, and the tappet spherical surface and the camshaft cam tip will wear compulsively.

- The corresponding pressure of the valve spring must not be too high, otherwise the camshaft cam tip and the valve tappet spherical surface will intensify the wear, resulting in excessive valve foot clearance and strange noise, and the clearance will be difficult to be excluded after adjustment.